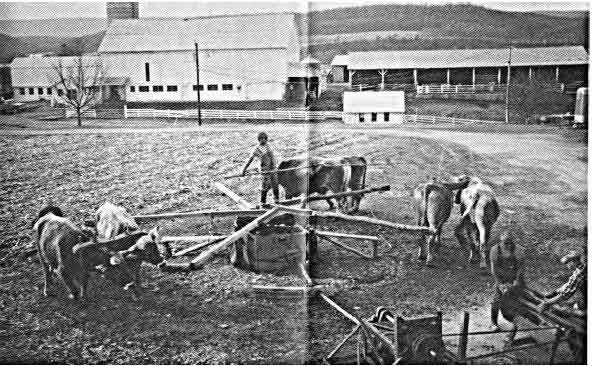

Hare Krsna dasi: Gita-nagari's Ox Power Unit was built in 1985 as a project of Gita-nagari's Adopt-A-Cow program, to demonstrate the value of working oxen using improved alternative technology. For about five or six years, the oxwn provided all the heating requirements for 60 residents of the farm. Residents selectively cut trees on the hillsides, and oxen pulled them down to the ox unit, where they were sawed to the wood-stove specifications for the temple and various homes. The oxen then delivered the cord wood to each location around the community.

Gita-nagari’s Ox Power Unit

by Hare Krsna dasi

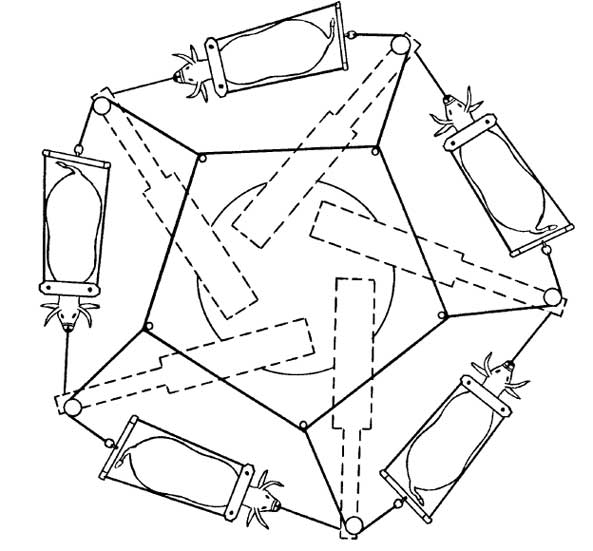

In this article we will describe how we built an ox-driven, sweep-powered generator. The concepts behind the design and operation of this unit are not new or complicated. Throughout history all over the world, man has used the same principles to produce power from draft animals. Traditionally, the mechanisms used to produce power have been made of wood, but we have constructed our generator from metal components, with the objective of maximizing the strength and efficiency of the unit.

Five oxen pull the tongues which a circular motion. Then, the motion is geared up, and the direction of the rotation is changed so that we end up with a shaft spinning at 765 rpm that will provide 60 horse-power. By using various types of pulleys off the final shaft, any range of speed can be achieved to drive any type of equipment desired.

To construct a machine similar to ours, you must have access to certain raw materials and the facility to convert them for usage. The sizes and strength of the components used in this unit have been carefully engineered and coordinated, so that any reduction of the given specifications will undoubtedly result in failure. In our case, many of the parts we used were not new, but we made it a point to be sure that used components were of good quality. Precision is essential. At one point, we ran into a lot of trouble with a used 2 3/16″ shaft that was 4′ long, but 1/10000″ out of round.

Much of the work involved can be done with basic metal working tools, but there is also a lot of work that must be done by skilled machinist. We did most of the work ourselves with an oxy-acetelyne torch, electric arc-welder, drill press, and similar tools. In addition you must have access to a metal lathe. We were lucky to have a neighbor who does this work as a second job, so we avoided paying the inflated prices of a specialty metal-working machine shop. What follows is a section-by-section description of how the unit is constructed.

(Full article with 26 technical drawings attached.)

— Hare Krsna dasi

Speak Your Mind